Structural design formulas for penstocks embedded in rock

The structural design formulas for penstocks embedded in rock which are shown in 'Technical standards for gates and penstock' in Japan are described.

Allowable stresss of steel material

Welded joint efficiency

| Location of welding | RT or UT carrying out for more than 5% of welded joint length |

RT or UT carrying out for less than 5% of welded joint length |

|---|---|---|

| Factory welding | 95% | 85% |

| Site welding | 90% | 80% |

Required safety factor for buckling due to external pressure

Pipe shell

Stiffener

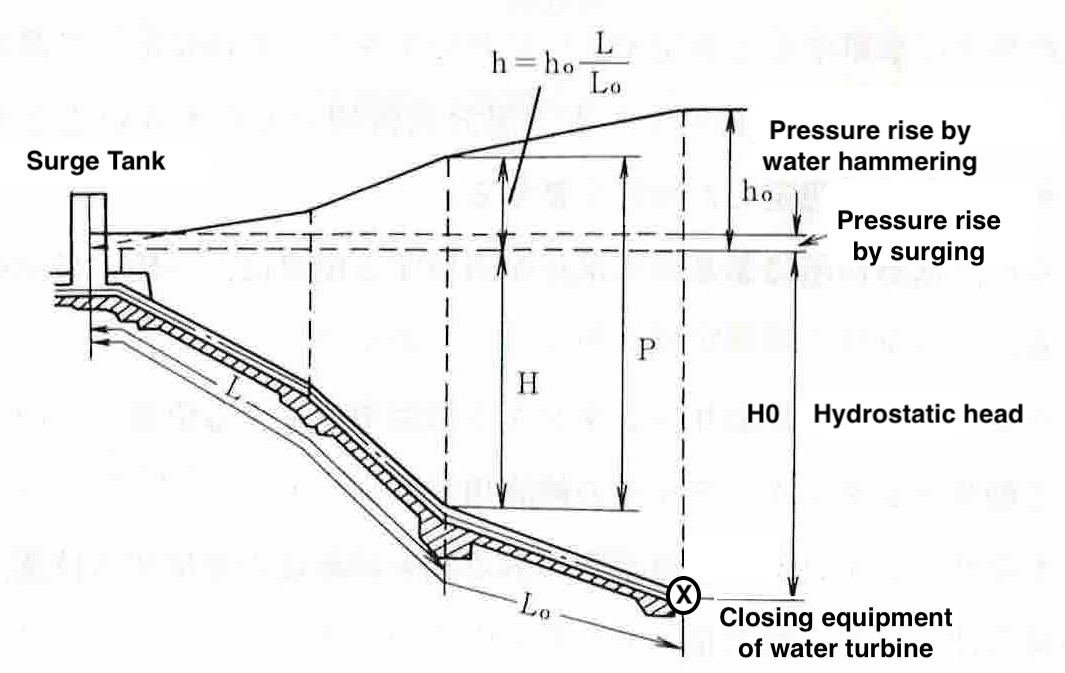

Design internal pressure

Definition of dimensions

Corrosion allowance

An allowance of more than or equal to 1.5mm shall be provided against corrossion and wear.

Minimum shell thickness

The minimum shell thickness used for the pressure lining part shall be more than or equal to those determined from following formula, if stiffeners are not used.

The minimum shell thickness shall not be less than 6mm even if the pipe diameter is small and stiffeners are used.

Stress calculation

Tensile stress in circumferential direction due to internal pressure

General

Internal pressure shared design by bedrock

Tensile stress in penstock axis direction

Stress due to restraint by stiffener

Stress due to temperature change

Stress due to Poisson's effect

Calculation for external presure

Without stiffener (E. Amstutz's formula)

With stiffener

Pipe shell proper (S. Timoshenko's formula)

Stiffener (E. Amstutz's formula)

That's all.